Pipetman Calibration Troubleshooting:

Printable Calibration Log

Printable Calibration Stickers (for use with Avery 5960 labels)

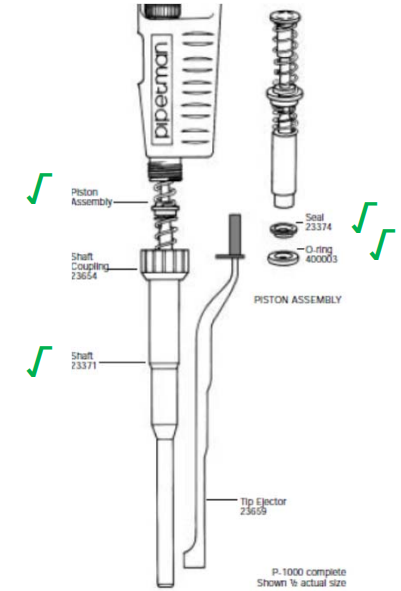

Before any Pipetman calibration adjustments are made, the seal, o-ring, shaft, piston, and pipette tip performance needs to be confirmed as being good and fully functional. These five (5) components account for 95% of all pipette performance issues with accuracy and precision (percentages below). Calibration adjustments are always the last resort after determining that the following parts are in good condition and functioning well:

- Seal and O-Ring 60%

- Piston 20%

- Shaft and Tips 10%

- Pipette Handle/Body 5%

Troubleshooting Pipetman calibration adjustments after confirming that the 5 Parts above are fully functioning:

- For pipettes that have three (3) silver calibration screws on the upper side portion of the volume adjustment knob and that are within the serial number sequence of H-79xxxxx – N-85xxxxx: Loosen the two-piece piston assemblies (introduced June 1982 [G-82xxxxx]) with a 2mm Allen wrench. Do not loosen the three (3) bottom brass colored screws. The upper three silver screws must be loosened before calibration is permissible.

- If the upper, silver screws will not loosen due to being stripped, try a 3mm Allen wrench or a special drill bit that removes stripped or damaged screws.

- Use a cordless drill on slowest speed setting and replace the three silver calibration screws.

- For pipettes that have a black, plastic, 6-hole calibration screw that won’t turn:

- This could be due to:

- The calibration screw is already adjusted to its maximum allowable range.

- The coefficient of expansion and contraction of the plastic parts in changing environmental conditions and over time. Expansion and contraction of the plastic has a subtle impact in cold/hot seasons.

- Black calibration screw threads could be stripped or cross-threaded.

- Gently clean and scrub the top of the calibration screw with IPA and a soft-bristled toothbrush. This is a difficult task, requires skill, and has a low success rate.

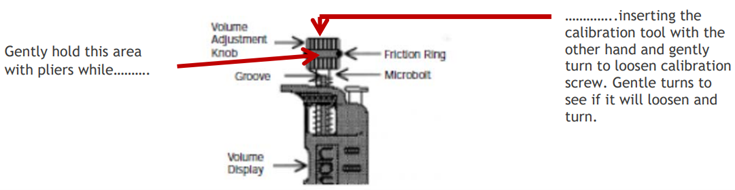

- If the calibration screw won’t adjust after the 1st attempt, gently hold the black volume adjustment knob and friction ring with pliers (see tip below). Simultaneously, attempt to adjust the calibration with the calibration tool in the other hand. The extra leverage of the pliers holding the volume adjustment knob in place may provide the necessary torque when using the calibration tool to adjust.

- This could be due to:

PROFESSIONAL TIP:

Use rubber grips for the end of your pliers or wrench. The rubber helps to prevent damage to the friction ring and micro bolt. These can be purchased at any local hardware store or online.

You can also buy plastic shrink tubing, cut it to the desired size, and heat/shrink it in place it over the plier nibs. This is the cheaper option; however, the tubing only lasts 2-3 months before it needs to be cut off and replaced.

Reminder: Adjusting the calibration should always be a last resort after the seal, o-ring, shaft, piston, and tips have been deemed fully functioning.

Overall, if the calibration screws cannot be adjusted, we recommend sending the pipettes to a calibration service provider. The pipette may require replacement of the calibration screw and/or the volume adjustment knob.

Pipetman Calibration Tools/Instructions:

Pipetman Calibration Wrench, Item # 27777

Gilson Pipetman L Calibration Tool, Item # 28888

Related Posts:

Pipette Parts – Life Span, Life Cycle, and Performance

Counter Assembly Instructions for Gilson Pipetman / Rainin Classic

Styles of Gilson Pipette Tip Ejectors

Differentiating Between Different Gilson Pipetman Eras

Gilson Pipetman Teflon vs. Polyethylene Seals

Disclaimer: Any action you take using the information on this website is strictly at your own risk. The information herein does not constitute professional advice and is general in nature. We make no warranty that this information will meet your requirements, be safe, accurate, or error-free. Pipette Supplies, Inc. is not responsible for any errors or omissions, any results obtained from the use of this information, or any loss or damage arising out of the use of this information. This site is for educational purposes only.

Fair Use: Copyright Disclaimer under section 107 of the Copyright Act of 1976, allows for “fair use” for purposes such as comments, criticism, teaching, scholarship, news reporting, and research.

Fair use is permitted by copyright statute that might otherwise be infringing.