Sartorius mLINE 5000uL Piston Cleaning & Preventive Maintenance

Recommended Tools and Parts:

- Foam Swabs (cotton swabs not recommended)

- Sartorius Lubricant (SA LH-731141)

- Lint-free towels (kim wipes)

Note: As Preventive Maintenance (PM) is performed, there may be a need to replace one or more of the following parts based on pipette part condition and wear and tear.

- mLINE Piston

- O-ring

- Shaft

- Lubricant

- Shaft, O-Ring, & Piston Assembly (SA 726097). Only sold as a kitted item not individually as shown.

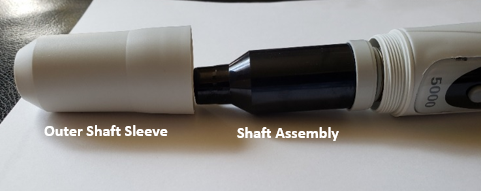

Step 1:

Loosen the outer shaft sleeve by carefully unscrewing it. Once unscrewed, remove and lay aside for reassembly later.

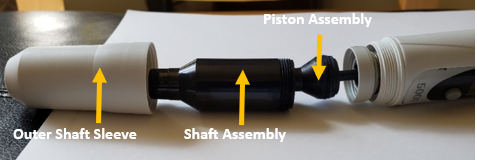

Step 2:

Loosen the black colored shaft assembly from the body by carefully unscrewing it. Once fully unscrewed, lay aside for preventive maintenance

Note: When the black shaft assembly is removed, you may see visible lubricant on the piston as well as inside the large orifice open of the shaft. This is okay and will be cleaned during PM.

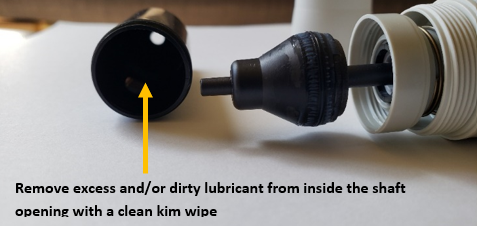

Step 3:

With the piston now exposed, use a clean kim wipe to gently wipe and remove any lubricant, chemical splash, or debris from the piston as well as inside the large portion of the shaft opening.

Note: Repeated wiping with the same kim wipe is not recommended. Please wipe only once and disregard to avoid scratching the piston, piston o-ring, and inside of the shaft.

Step 4:

With the shaft now exposed, use a clean kim wipe to gently wipe and remove any lubricant from the piston as well as inside the large portion of the shaft opening.

Note: Be sure the piston and shaft do not have any visible amounts of lubricant after cleaning.

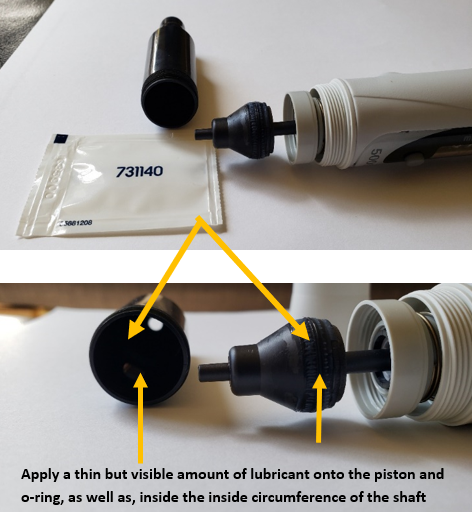

Step 5:

With a clean foam swap, apply a thin amount of the Sartorius pn: SA LH-731141 onto to it. Gently coat the piston o-ring with a thin layer of lubricant around the entire circumference of the piston o-ring.

DO NOT over apply with a thick coat of lubricant. Just enough for it to be seen visibly on the piston o-ring.

Step 6 Reassembly:

Reattach and carefully screw the black shaft onto the mLINE piston assy.

Step 7 Reassembly:

Reattach the outer shaft sleeve to the piston by carefully screwing it onto the body.

Helpful Tip: Once the pipette is fully reassembled, set the pipette volume to 5000uL and place a 5000uL tip onto the shaft.

- Fully aspirate 5000uL Di water into the tip

- Slowly withdrawal the tip from the di water reservoir

- With the water still in the tip, count to 10. The purpose is to see if any visible leaks will occur before proceeding to the next step.

- If a leak is detected, please disassemble, remove lubricant, and reapply. If leak still occurs then it may be possible that the piston, o-ring, and or shaft may need to be replaced.

Step 8:

After a successful liquid leak test, allow the pipette to equilibrate for at least 60 minutes to ambient conditions after preventive maintenance (PM) is complete.

Step 9:

Once the equilibration period has ended, verify pipette accuracy and precision on a 4-5 place balance. If pipette meets acceptable accuracy and precision requirements then use freely. If it does not, please contact us at Pipettesupplies.com for additional support.

Printable Calibration Log

Printable Calibration Stickers (for use with Avery 5960 labels)

Disclaimer: Any action you take using the information on this website is strictly at your own risk. The information herein does not constitute professional advice and is general in nature. We make no warranty that this information will meet your requirements, be safe, accurate, or error-free. Pipette Supplies, Inc. is not responsible for any errors or omissions, any results obtained from the use of this information, or any loss or damage arising out of the use of this information. This site is for educational purposes only.

Fair Use: Copyright Disclaimer under section 107 of the Copyright Act of 1976, allows for “fair use” for purposes such as comments, criticism, teaching, scholarship, news reporting, and research.

Fair use is permitted by copyright statute that might otherwise be infringing.